Fickert Final

Fickert Final Specification

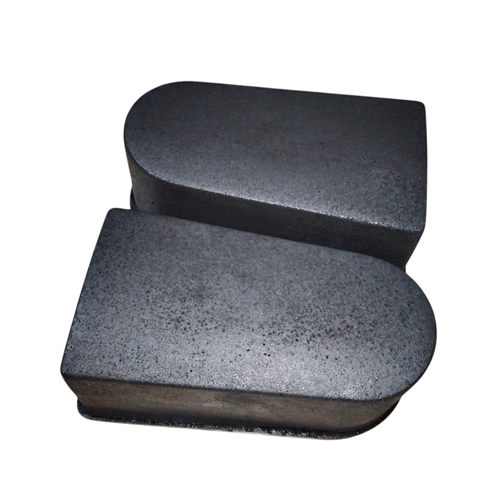

- Shape

- Fickert

- Usage

- Industrial-Granite Polishing

- Material

- Diamond Powder

- Size

- Customized

- Type

- Fickert Resin Bond

- Color

- Black

Fickert Final Trade Information

- Minimum Order Quantity

- 6 Pieces

- Delivery Time

- 5 Days

About Fickert Final

Fickert Final Abrasive is a high-quality industrial abrasive designed for precision finishing. Crafted from durable stone, it ensures optimal performance in demanding industrial applications. Its rectangular shape is engineered for compatibility with various machinery setups, while the customizable size options meet diverse operational needs. The sleek black color enhances its aesthetic appeal while highlighting its robust craftsmanship. As a trusted solution for efficient and reliable finishing processes, this abrasive delivers consistent results, maximizing productivity for manufacturers, suppliers, and traders. Whether addressing large-scale industrial requirements or tailored operations, this product is built to withstand rigorous usage while maintaining excellent performance standards. Fickert Final Abrasive is Used to give final polish on granite & marble on Line polishing machines.

Used to give final polish on granite & marble on Line polishing machines

FAQs of Fickert Final Abrasive:

Q: What material is used in Fickert Final Abrasive?

A: The abrasive is made from high-quality stone to ensure durability and efficiency in industrial applications.

Q: Is the size of the abrasive customizable?

A: Yes, the size can be customized to meet specific operational requirements.

Q: What shape does the abrasive come in?

A: The product features a rectangular shape for compatibility with a variety of machinery setups.

Q: What is the color of this abrasive?

A: It is available in a sleek black color, which highlights its robust design.

Q: Who can benefit from this abrasive?

A: Manufacturers, suppliers, and traders seeking reliable finishing solutions for industrial applications can benefit from this product.

Precisely Engineered for Granite Polishing

Our Fickert Resin Bond abrasives are meticulously designed using diamond powder for the highest efficiency during the final stages of granite polishing. Their Fickert shape ensures optimal contact and smooth operation, while the customizable size options provide adaptability to different machines and applications.

Trusted Indian Manufacturing and Distribution

We stand out as a leading manufacturer, supplier, distributor, and trader of Fickert Final products in India. Our commitment to quality control, rapid fulfillment, and tailored customer support makes us a preferred partner for industrial granite polishing professionals nationwide.

FAQs of Fickert Final:

Q: How is the Fickert Final with resin bond used in granite polishing?

A: The Fickert Final, designed with resin bond and diamond powder, is attached to granite polishing machines at the final stage. Its robust composition delivers a smooth, high-gloss finish, ensuring consistent results across large surfaces.Q: What advantages does diamond powder offer in the Fickert Final tool?

A: Diamond powder enhances cutting efficiency, accelerates polishing speed, and delivers exceptional durability, reducing the need for frequent replacements. It achieves a mirror-like finish on granite surfaces with minimal effort.Q: When should I opt for a customized size for the Fickert Final abrasive?

A: Choosing a customized size is ideal when your granite polishing machines require specific dimensions or when unique operational needs arise. Our team can fabricate Fickert resin bond tools tailored precisely to your equipment.Q: Where can I source Fickert Final abrasives in India?

A: We serve as a reputable manufacturer, supplier, distributor, and trader of Fickert Final abrasives throughout India, supporting customers with swift delivery and comprehensive after-sales service.Q: What is the process of installing the Fickert Final on granite polishing machines?

A: Installation involves securing the customized Fickert abrasive onto compatible machine heads, ensuring they are tightly fitted. Regular inspection is recommended for maximum performance and safety during operation.Q: What are the benefits of using the Fickert shape in granite polishing tools?

A: Fickert-shaped abrasives provide superior stability and consistent surface contact, leading to enhanced polishing efficiency and uniform granite finishes, especially on large or irregular surfaces.

Price 350.0 INR/ Piece

- Minimum Order Quantity

- 6 Pieces

- Delivery Time

- 5 Days

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Fickert Final Abrasive Category

Fickert Final Abrasive

Price 350.0 INR / Piece

Minimum Order Quantity : 6 Pieces

Color : Black

Usage : Industrial Granite Slab Polishing

Size : Customized

Type : Fickert Resin Bond

Fickert Lux Big Size

Price 350.0 INR / Piece

Minimum Order Quantity : 6 Pieces

Color : black

Usage : IndustrialGranite Polish

Size : Customized

Type : Fickert Resin Bond

Fickert Lux Ultra Small

Price 350.0 INR / Piece

Minimum Order Quantity : 6 Pieces

Color : Black

Usage : Industrial Granite Polishing

Size : Customized

Type : Fickert Resin Bond

Fickert Lux Ultra Big

Price 350.0 INR / Piece

Minimum Order Quantity : 6 Pieces

Color : Black

Usage : IndustrialGranite Polishing

Size : Customized

Type : Ficker Resin Bond

Send Inquiry

Send Inquiry Send SMS

Send SMS